Dear Mrs. Rooney,

on behalf of the German Initiative Pro Li-Ionen-Batteries I`m writing this message to you.

The ICAO, the International Civil Aviation Organization (ICAO), invests a great deal of effort into Li-ion batteries, in particular concerning safety on board civilian aircraft.

Li-ion batteries have become our daily companion; these accumulators from the family of Li-ion batteries are able to offer a high level of safety in transportation and application. The many billions of these batteries used today verify this claim.

However, to our deep regret, some batteries do provide the exception to the rule, as is the case for the Phablet recently. Pertinent regulations exist on transportation which restrict the use of lithium batteries in air traffic.

We place great importance on safety developments in air traffic. Here we have observed the development of regulations for many years, and have noticed diverse developments which are not necessarily orientated to the overall target, and which generate a high level of effort and expense.

Two examples of this are the restrictions on loading condition and the more general regulations for tests and criteria as in the field of Quality Assurance.

We would be happy to contribute towards the objectification and improvement of these regulations.

We feel that the regulations on the quality specifications should be made more specific.

One possible suggestion would be the definition of new requirements which, seen short-term, would mean a substantial advancement in the safety of real applications.

To name some specific examples: The final inspection criteria should be specified as equal to the automobile industry standards. In addition, it would be feasible to specify error point detection in the QSP processes. This should also apply to technologies such as the contact-free ultrasonic inspection equipment (airborne ultrasound).

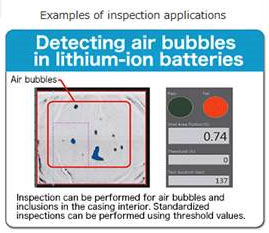

Ultrasonography is a contact-free inspection method that passes ultrasonic waves through materials to create an image (graph) using sound (sono). This method allows for non-destructive, contact-free inspection for air bubbles, separation, and foreign materials inside parts.

Ultrasonic inspection allows for clear detection of air bubbles, separation, and other problems that are difficult to detect with X-ray inspection.

Source: Yamaha - Japan

These are only a few initial examples, which however make a major contribution towards increases in safety.

We would be happy to incorporate our suggestions.

We would be extremely grateful to you if you could provide us with an opportunity to do so. We would like to thank you in advance at this point for your esteemed support, and eagerly await your reply.

With the compliments of

Tim Schäfer – Initiative Pro Li-Ionen-Batterien (Pro Li-ion Battery Initiative)

www.li-ionen-batterien.de